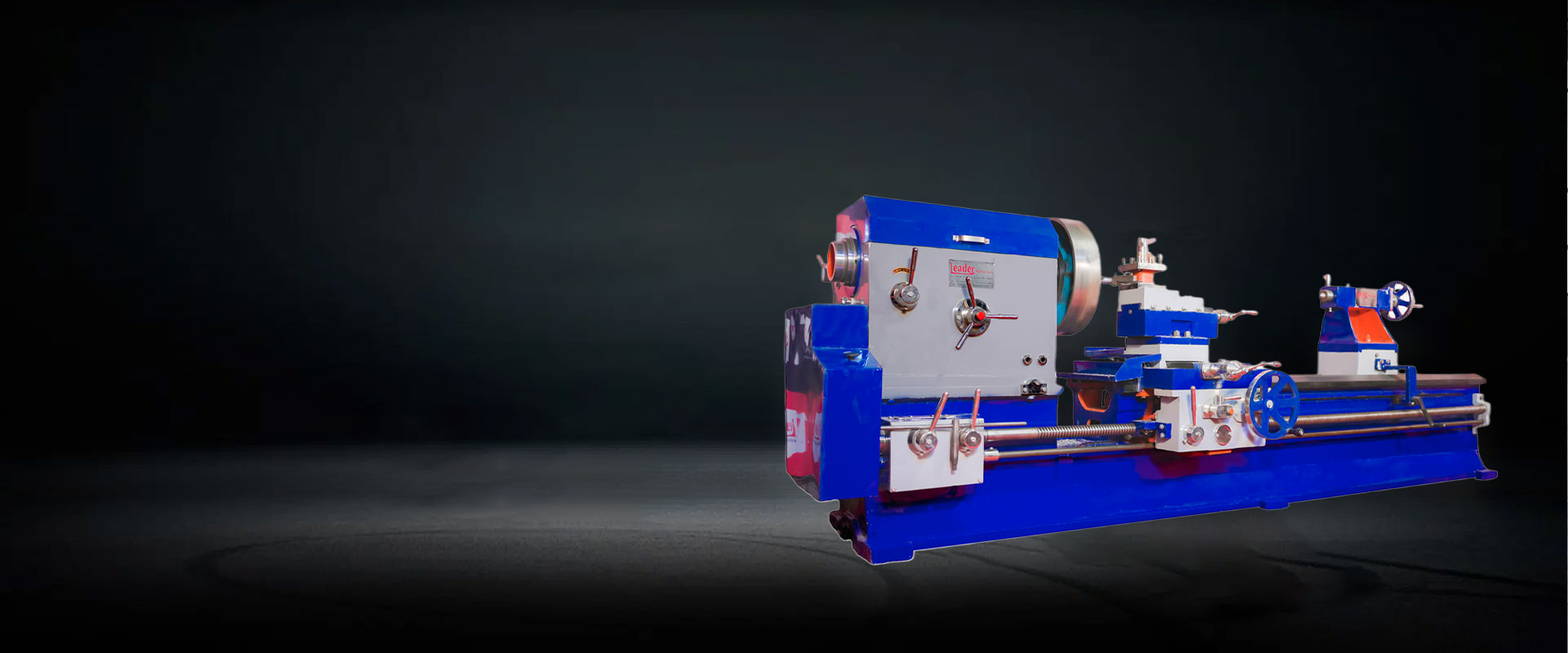

Top Lathe Machines Manufacturers

Upgrade your machining capabilities with precision and reliability. As one of the Top Lathe Machine Manufacturers, we specialize in crafting robust and efficient machines that empower industries. Explore our cutting-edge solutions, designed to meet the demands of modern manufacturing and deliver unparalleled performance at every turn.

Greetings and welcome to the digital abode of Leader Machine Tools, where precision meets innovation, and excellence is a tradition. As a testament to our commitment to quality, we proudly stand as one of the Top Lathe Machine Manufacturers, seamlessly blending cutting-edge technology with decades of expertise. At Leader Machine Tools, our mission is to empower industries with state-of-the-art machinery, revolutionizing the manufacturing landscape.

Our Legacy of Excellence:

- Established with a vision to redefine precision engineering, Leader Machine Tools has been a cornerstone in the manufacturing sector for many years.

- We have carved a niche as leaders in the industry, consistently delivering unparalleled quality and reliability in every machine we produce.

- Our legacy is built on a foundation of trust, with a customer-centric approach that places your needs at the forefront of everything we do.

At Leader Machine Tools, we take pride in setting benchmarks with each machine we produce. Our lathes are engineered to perfection, combining cutting-edge technology with robust construction to ensure optimum performance. Here's why our lathe machines are the preferred choice:

- Precision Redefined: Our lathe machines are crafted with utmost precision, enabling you to achieve intricate and accurate machining for various applications.

- Durability: Built to withstand the rigours of industrial operations, our machines are synonymous with durability, ensuring a long and trouble-free service life.

- Versatility: From small-scale workshops to large industrial setups, our lathe machines cater to a diverse range of applications, showcasing unparalleled versatility.

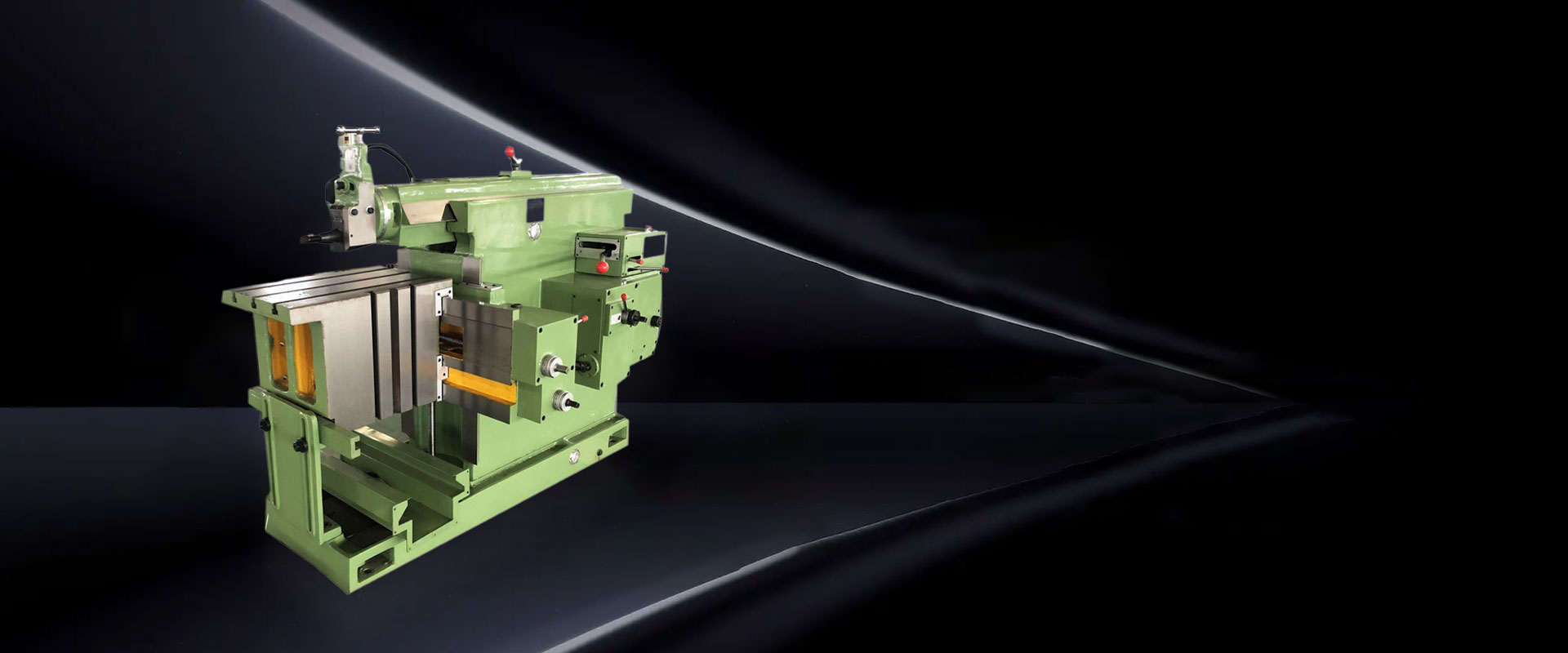

Leading Lathe Machine Manufacturers in India

We have a wide range of lathe machines in India that are used in various systems and applications. These machines are available in various models and sizes. They are suitable for different types of applications and industries. As one of the Leading Lathe Machine Manufacturers in India, we take pride in contributing to the growth of the manufacturing sector in the country. Being one of the Best Lathe Machine Manufacturers, we manufacture machines that are cost-effective and provide high-performance results.

Our commitment to quality and innovation has made us the preferred choice for businesses across industries. Here's what sets us apart:

- Advanced Technology: Embracing the latest technological advancements, our machines are equipped with state-of-the-art features that enhance efficiency and productivity.

- Custom Solutions: Recognising the unique needs of our clients, we offer customised solutions, tailoring our machines to meet specific requirements.

- Comprehensive Support: Our dedication to customer satisfaction extends beyond the purchase. We provide comprehensive support and maintenance services to ensure your machines operate at peak performance.

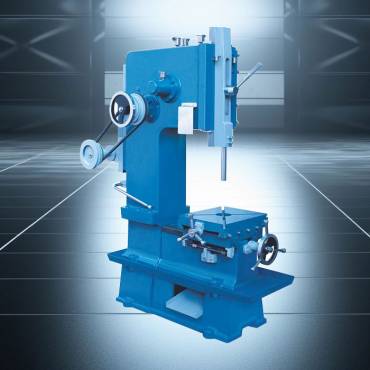

All Geared Lathe Machine Suppliers in India

Our commitment to quality and innovation has made us the preferred choice for businesses across industries. We are a trusted partner of businesses across the world and have developed a strong foothold in the Indian market. In addition to being pioneers in lathe machine manufacturing, Leader Machine Tools takes pride in being prominent All Geared Lathe Machine Suppliers in India. Our foray into the agricultural sector aims to support the backbone of our nation – the farming community. Here's why our cattle feed machines stand out:

- Nutrient-Rich Feed: Our machines are designed to produce high-quality cattle feed, ensuring that livestock receives the essential nutrients for optimal health and productivity.

- User-Friendly Design: Simple and efficient, our cattle feed machines are user-friendly, making them accessible to farmers of all scales.

- Economic Viability: With a focus on cost-effectiveness, our machines contribute to the economic viability of cattle farming, promoting sustainability in the agricultural sector.

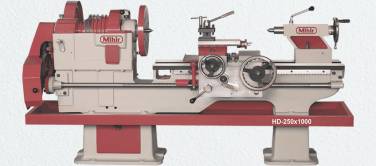

All Geared Lathe Machine Exporters in India

We have a long list of satisfied clients from all over the world. Our products are not only popular in India, but also popular in many countries. As All Geared Lathe Machine Exporters in India, Leader Machine Tools extends its reach globally, contributing to the agricultural landscape beyond borders. Our commitment to quality transcends geographical boundaries, and here's why our machines are sought after worldwide:

- International Standards: Our cattle feed machines adhere to international quality standards, ensuring that they meet the expectations of farmers and businesses globally.

- Global Reach: With a robust export network, we bring the excellence of Indian manufacturing to the world, supporting agricultural communities in various countries.

- Collaborative Partnerships: We believe in building collaborative partnerships, working with clients globally to address the diverse needs of the agricultural sector.

At Leader Machine Tools, we are more than just manufacturers; we are partners in your journey towards precision, efficiency, and growth. Whether you are in need of top-notch lathe machines or reliable cattle feed solutions, we stand ready to exceed your expectations. Join us in shaping the future of manufacturing and agriculture, where excellence is not just a standard but a way of life. Welcome to Leader Machine Tools, where innovation meets precision, and your success is our priority.

More About

Us